Preparations before the operation

The task was mainly to observe the "conductor guides" when we lowered the drill string and conductor pipes through the jacket structure of Ivar Aasen. The operation is necessary to prevent damage to the equipment, which can lead to significant delays in the project. The assignment is also part of Aker BP's incentive to cut costs by possibly reduce the use of work-class ROVs in simple marine operations.

We carefully observed the weather with a forecast of significant wave height and wind speeds. With a wind speed of about 10-15 m/s and waves of 2-3 Hs, we decided to try to launch the Blueye drone. In order for it to be safe to lower it down over the railing, a simple launching rig was made consisting of a small anchor roll bar mounted on a cable rail which in turn was mounted to the railing.

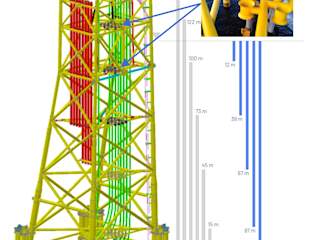

The drone was lowered 38 meters down from the Texas deck before entering the water. Although we had previously feared that the underwater vehicle would be like a pendulum, it was unproblematic to lower it down to the waves. When the mini-ROV hit the surface, all we had to do was to release enough on the tether, hold down the boost button, and fly over to Ivar Aasen's structure through the waves that broke around the truss. With auto-heading, it was neither a problem to keep the direction even in this wave foam. When we came down to a depth of 12-15 meters, it calmed down considerably, and we quickly spotted the first level with conductor guides.

The crystal clear water and the good daylight made it easy for us to orientate. As we got further down, it got darker and murkier, but that also went just fine with the drone's powerful light, as long as we kept parts of the structure in view. As there was a lot of current and power from the waves, the battery emptied relatively quickly. We ended up with a diving time of about 75 min after being down on the lower conductor guide at 100 m depth. You could easily see the drill string rotate as we drove up to the surface again. Finally, we pulled in the tether's slack before lifting the drone by hand over the anchor roll bar.

The ROV guys

The crew also operated another ROV. It was relatively small but still six times heavier than the Blueye mini-ROV. They had rigged a container on deck with a team of four men who went 12-hour shifts. These guys had extensive experience as ROV pilots from the North Sea in companies such as IKM Subsea and Oceaneering. Their craft was a Saab Seaeye Falcon equipped with both grippers and multi-beam sonar. We also installed a PH sniffer (mounted in front) to verify that the cement had reached the very top around the conductor in the hole.

One of the pilots was also interested in testing the Blueye drone and launched the drone. After a Work Permit and a Toolbox Talk was conducted, he lowered the drone to the water. The pilot stood with the controller and was quickly super impressed with the underwater robot's maneuverability and balance.

This is by far the best mini-ROV I've ever tried, and I'm not just saying it to be nice!

- ROV Pilot for IKM Subsea

Furthermore, he liked the image quality and how little backscatter there was in the image. With the image stabilization enabled, we got some excellent pictures taken of the drill string that was turning around inside the conductor guide at 40 m depth. The driller was also pleased with his video stream's image quality up in the doghouse, routed up via a temporary ethernet cable.

The Blueye drone managed the mission and came to the bottom of Ivar Aasen in the North Sea, although we were still dependent on some functions such as "bubble watch" and PH measurement from the Falcon ROV.

ROV-Breakdown

After leaving the North Sea, Blueye received a phone call from the rig, telling that their ROV had crashed and that it was impossible to get spare parts until over the weekend. Thus, Blueye suddenly became the main ROV on top hole no. 2. The ROV-boys then had the launch rig mounted again and put out Maersk Drilling's own Blueye drone.

Did you get any benefit from the drone? We got to take pictures of the conductor implementation as desired by the customer. It got a good test with launch from the Texas deck in 2 m+ Hs, 0.5 knots current, 110 m water depth and otherwise demanding conditions. Quite impressive even without sonar or positioning equipment.

- ROV Pilot for IKM Subsea

Later, after returning to the office in Trondheim, we also received good feedback from Hanna in Aker BP:

Blueye drone provided good support on top hole no. 2. Although we did not get to see everything we wanted due to the battery life, we got what we needed to continue the operation.

- Hanna Tronstad, Assistant Drilling Superintendent Aker BP